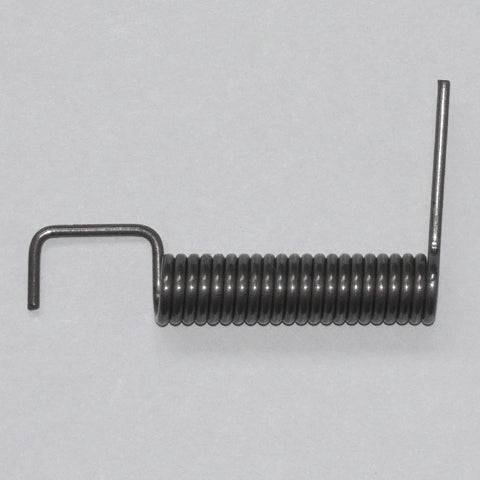

13.5mm Letter Plate Spring with Cranked Arm (1.3mm wire), Pack of 2

UK P&P £2.45 (Second Class) or £3.45 (First Class) per shipment irrespective of the number of items in your order. Please select either First Class or Second Class at checkout. Many of our products are also available on Amazon (Google ‘Northern DIY Amazon’ to see if this product is available). Orders placed on Amazon are dispatched by Amazon from stock we place in the Amazon warehouse. P&P is free on Amazon if you have Amazon Prime.

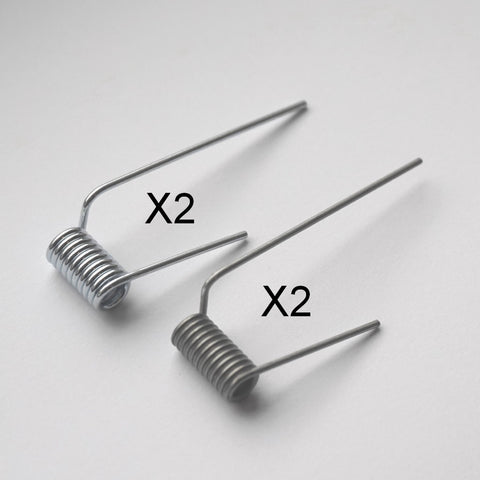

Pack of 2 Letter Plate Springs. Suit rods up to 4.5mm diameter. These springs are made from 1.3mm diameter wire and are stronger than the similar 14.5mm spring with a cranked arm that we sell which are made from 1.2mm wire. These springs are suitable for Trinity style letter plates (with a vertical flap) which generally require a stronger spring. They can also be fitted to letter plates with a horizontal flap, giving a firmer feel than the 14.5mm spring. The springs are fitted between the two hinges. Either 1 or 2 springs can be used as required. Dimensions are given in the additional photographs.

Fitting Instructions

Although the instructions are slightly different, it may help to look at the picture in our guide 'How to Fit a Letter Plate Spring' when reading the following instructions.

Disclaimer: These instructions are provided subject to our general Terms of Service (accessed by clicking the link at the bottom of the page). Wear appropriate hand and eye protection as springs have sharp edges and can recoil with force.

1) Slide rod out of the right hand hinge, but leave rod in the left hand hinge.

2) Slide new spring over rod with both arms pointing up. The arm with the crank should be on the RHS.

3) Rotate the RHS (cranked) arm of the spring under the rod to rest against flap. Sometimes it might be easier if the rod is only partially inserted into the LHS of the spring as you rotate the Right Hand (cranked) arm under the rod.

4) Slide rod back through the Right Hand hinge.

Unless the spring is being fitted to a trinity (vertical) letter plate, at this point the LHS arm of the spring is probably still extending above the frame of the letter plate. You can now either

a) Cut off the excess so the arm sits within the frame of the letterplate or

b) Put a 90 degree bend in the LHS arm of the spring so that this arm runs along just below the top edge of the frame.

If the LHS arm is cut too short it will just spin around under the rod, so often b) is safer. You can always straighten and re-bend the arm. If you cut too much off you can't stick it back on! The LHS arm always rests against the inside of the letter plate frame, it doesn't rest against the rod.

We Also Recommend